In the fields of mineral processing and scientific research experiments, the shaker, as a key piece of equipment, its precise selection directly affects production efficiency and experimental results. As a professional shaker manufacturer, Jiangxi Mingxin has launched a product series covering multiple scenarios such as mineral processing and laboratories. Faced with a rich variety of types, it is crucial to master scientific selection methods. As long as you follow the three-step rule of "clarifying the purpose, matching samples, and evaluating performance", you can easily find the most suitable shaker equipment.

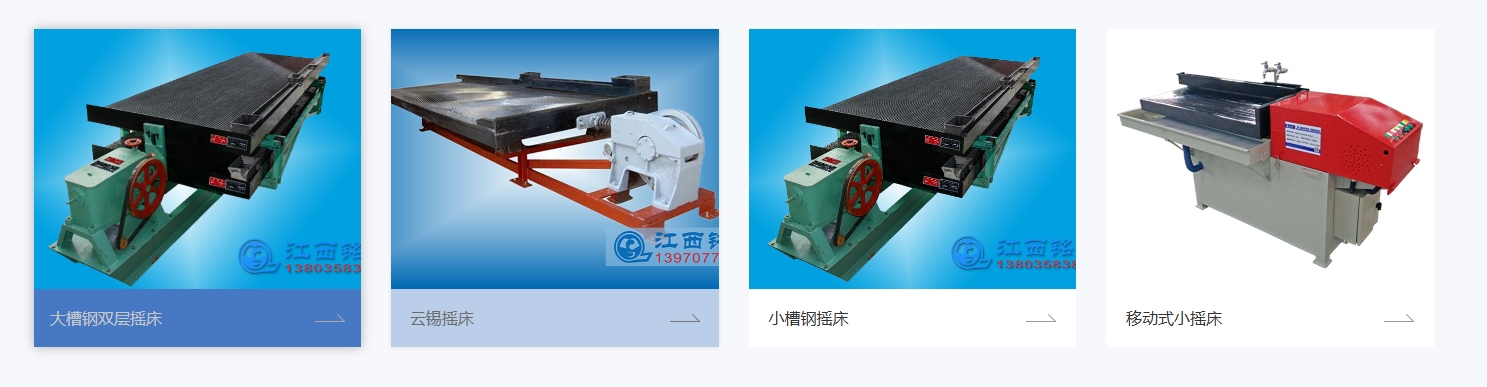

The first step is to clarify the purpose of use, which is the basis for selection. The functional requirements for shakers vary greatly in different scenarios. Only by first identifying the purpose can the range of choices be narrowed down. If it is used for mineral separation, the double-layer shaker for mineral processing of Jiangxi Mingxin is the preferred choice. It significantly saves floor space with its compact design and has an extremely large processing capacity. It can directly separate the final concentrate and tailings in a single operation, eliminating the trouble of multiple processing. It is particularly suitable for the purification of rare and precious metals such as tungsten, tin and gold, and can also efficiently process common minerals such as iron, manganese and coal, providing strong support for mineral processing enterprises to improve production efficiency. If it is a laboratory setting, the selection should be made based on the specific type of experiment: when conducting chemical experiments such as Coomas blue staining and electrophoresis gel fixation, the gentle oscillation of the decolorizing shaker can ensure the uniform reaction of reagents; When conducting biological experiments such as cell culture and bacterial culture, the stable operation of the track shaker can simulate a suitable growth environment. If there are strict requirements for temperature, the precise temperature control function of the constant temperature incubation shaker is indispensable, ensuring that the experimental conditions remain stable at all times.

The second step is to consider the characteristics of the sample, which is the key to selection. The core function of a shaker is to separate or cultivate samples. The inherent properties of the samples directly determine the compatibility of the equipment. For shakers used in mineral processing, the particle size and density of the ore are the core considerations. When the feed particle size is greater than 0.2mm, the large gap screen surface of the coarse sand shaker can prevent ore blockage and ensure smooth material transportation. When the particle size is between 0.2 and 0.074mm, the fine separation structure of the fine sand shaker can achieve more precise sorting. If the particle size is less than 0.074mm, the special bed surface design of the ore mud shaker can effectively handle fine ore mud and prevent material loss. Meanwhile, the greater the density difference of the ore, the more significant the separation effect of the shaker based on the density difference. When selecting the type, it is necessary to combine the characteristics of the ore to determine whether the equipment can achieve the best separation efficiency. For laboratory shakers, the size and weight of the samples are the key points. When conducting experiments with large-capacity culture flasks, a shaker with a larger amplitude should be selected to ensure that the liquid inside the flask is thoroughly mixed. When dealing with trace samples, a small-amplitude shaker can prevent sample splashing and ensure the accuracy of the experiment. In addition, it is necessary to confirm whether the load capacity of the shaker meets the requirements to prevent equipment failure due to overloading and affect the experimental process.

The third step is to pay attention to the parameters and performance of the equipment, which is the guarantee for selection. High-quality parameters and stable performance are the prerequisites for the long-term efficient operation of the shaker. It is necessary to carefully compare the details of the equipment. The power system of the mineral processing shaker is particularly crucial. The transmission structure composed of the motor at the head of the bed, the eccentric wheel and the connecting rod must be able to provide continuous and stable reciprocating motion power to ensure a uniform and consistent separation process. The flexibility of the slope adjustment device is also indispensable. By flexibly adjusting the slope of the bed surface, it can meet the separation requirements of different ores and improve the separation quality. At the same time, the energy consumption and durability of the equipment also need to be taken into account. Low-energy consumption design can reduce the operating costs of enterprises, while the body made of high-strength materials can extend the service life of the equipment and reduce maintenance investment. The parameters of the laboratory shaker are required to be more precise. The adjustable range of the oscillation frequency needs to match the experimental requirements to ensure that different intensity oscillation effects can be achieved. The temperature control range and accuracy directly affect the success or failure of biological experiments, so equipment with small temperature control errors should be selected. The amplitude size and timing range need to be flexibly adjusted according to the experimental process to make the experimental operation more convenient and efficient.

Say goodbye to the difficulty of making choices! Three core selection dimensions of Jiangxi Mingxin shakers-Industry News-Jiangxi Mingxin Metallurgical Equipment Co., Ltd.

Say goodbye to the difficulty of making choices! Three core selection dimensions of Jiangxi Mingxin shakers-Industry News-Jiangxi Mingxin Metallurgical Equipment Co., Ltd.