The movement patterns of water flow are quite different: symmetrical "swaying" vs. asymmetrical "fast rise and slow fall"

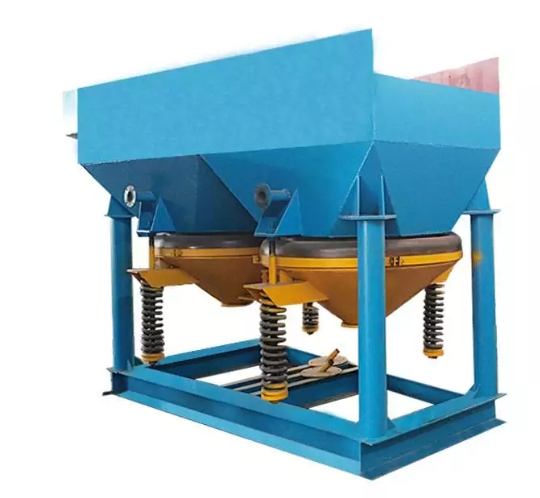

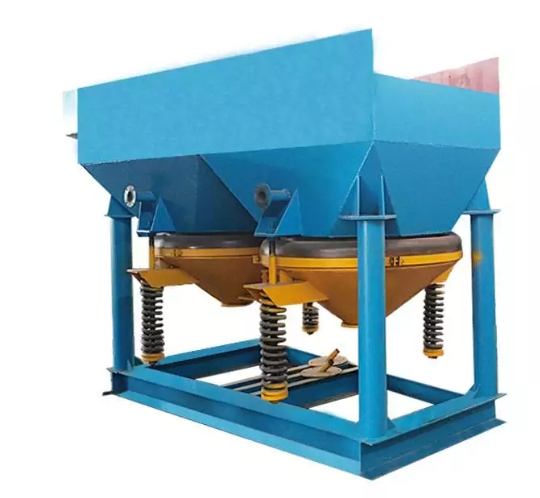

When mineral selection is carried out in mines, the jigging machine separates minerals of different densities by the up and down movement of water flow. The core difference between the diaphragm jigging machine and the sawtooth wave jigging machine lies in the way water flows. In traditional diaphragm jigging machines, the water flow moves up and down symmetrically like a pendulum - the speed and time for going up and down are approximately the same. As a result, the "activity space" for mineral stratification is relatively fixed. When encountering minerals of different coarnesses, it is difficult to distinguish them all clearly. However, the sawtooth wave jigging machine is different. It relies on a special mechanical structure to make the water flow "rise fast and fall slowly" : the time spent surging upwards only takes up 1/3 to 1/4, while the time spent falling downwards takes up 2/3 to 3/4. This "fast rush and slow fall" of the water flow can make the mineral layer more loose, and minerals of different densities can be separated more clearly.

Beneficiation effect and cost: Higher recovery rate and less water consumption

Judging from the actual usage effect, the gap between the two machines is quite obvious. Especially when selecting fine-grained minerals, the sawtooth wave jigging machine performs even better. For instance, in the gold mines of Yuanyang, Yunnan Province, the purity of the gold extracted from it can exceed 80%, and it can be directly refined after simple processing. Compared with diaphragm jigging machines, when selecting minerals such as tin, tungsten, lead and zinc, it can recover 3% to 5.5% more. Moreover, it is more water-efficient because the water flow design is more reasonable. There is no need to replenish so much water, and the water consumption can be reduced by 30% to 40%. At the same time, in the same area, it can process more minerals and is more efficient.

Which one should be used? Look at the actual needs of the mine

It's not to say that the sawtooth wave jigging machine is necessarily better; the key lies in the demands of the mine. If common non-ferrous metals are selected, the precision requirements are not particularly high, and it is large-scale production, then the traditional diaphragm jigging machine is sufficient. The technology is mature and stable. However, if there are special requirements, such as choosing coarse-grained barite and manganese ore with a maximum diameter of 60 millimeters, or selecting sand gold, fine-grained tungsten-tin ore, or even recovering metals from the remaining slag from smelting, then the sawtooth wave jigging machine is more suitable. Moreover, its parts can be flexibly combined and the speed can be adjusted at will. It is also convenient for small and medium-sized mines to use. Nowadays, many mines that pursue environmental protection are willing to choose it.

Jigging machine-Industry News-Jiangxi Mingxin Metallurgical Equipment Co., Ltd.

Jigging machine-Industry News-Jiangxi Mingxin Metallurgical Equipment Co., Ltd.