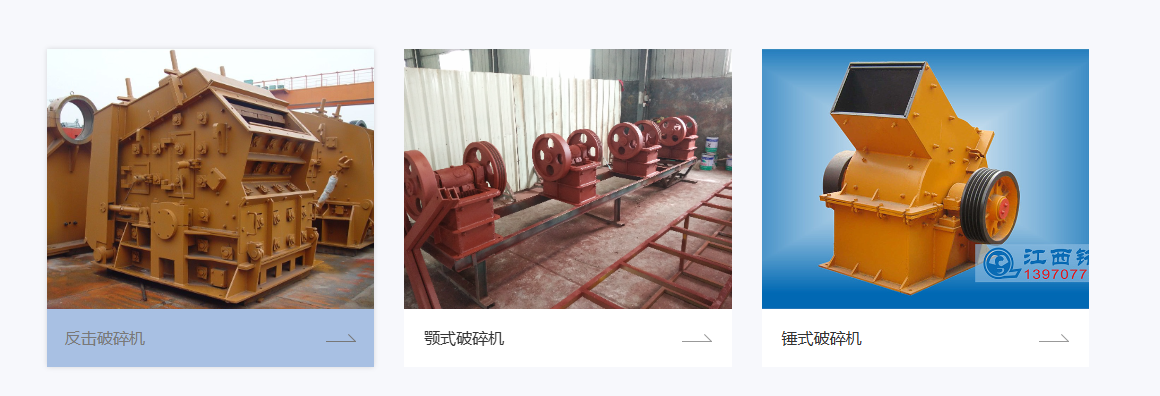

The Jiangxi Mingxin crusher series has established a complete product system, covering core fields such as plastic recycling, mining, and building materials processing, with the core advantages of "precise scene adaptation, efficient and stable operation, and low consumption and easy maintenance". This series mainly includes three categories: plastic crushers, jaw crushers, and hammer crushers. It can provide professional solutions for various industries, ranging from fine plastic recycling crushing to coarse and medium crushing of high-hardness ores, based on the characteristics of different materials and crushing requirements.

Core features of plastic and jaw crushers

The plastic crusher series focuses on plastic recycling and is further classified into three types of crushers: hard plastic, strong plastic, and pipe. They are respectively suitable for ABS sheets, various types of plastic products, and PE/PVC pipes. Structurally, they feature alloy steel blades, sound insulation design, and a movable base. In terms of performance, they have precisely matched motors, low energy consumption, and stable operation. The jaw crusher crushes materials by the squeezing of the movable and fixed jaws. Its core components are simple, the crushing chamber is deep without dead zones, and the discharge port is adjustable. It is widely used in the metallurgical and mining fields and can stably process medium and high-hardness ores such as granite. It is a core equipment for coarse crushing operations.

Key advantages of hammer crushers

The hammer crusher impacts materials through the high-speed rotor driving the hammer heads, and the materials are refined by secondary impact on the liner. It has a simple structure and comes in multiple types such as single-stage and high-efficiency. The equipment is lightweight and easy to install. Its crushing ratio reaches 10-50, with high production capacity, uniform finished products, low energy consumption, and is suitable for brittle materials such as limestone and coal gangue with a compressive strength of ≤150MPa. It is easy to operate and maintain, and is widely used in the building materials and chemical industries. It can efficiently crush large pieces of materials to the target particle size.

Overview of Jiangxi Mingxin Crusher Series-Industry News-Jiangxi Mingxin Metallurgical Equipment Co., Ltd.

Overview of Jiangxi Mingxin Crusher Series-Industry News-Jiangxi Mingxin Metallurgical Equipment Co., Ltd.