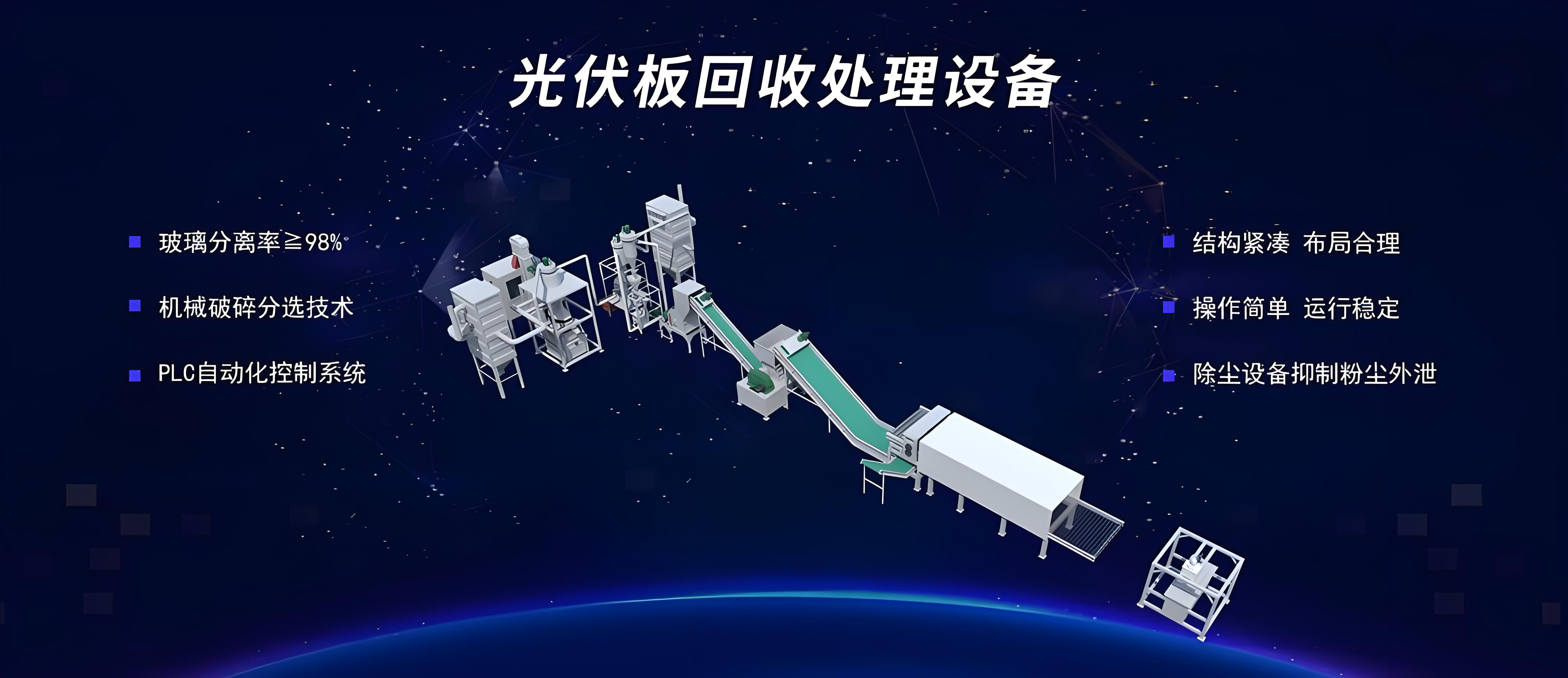

Product Description

Solar photovoltaic (PV) recycling is an emerging waste stream generated in both consumer and commercial sectors. Although the current demand may not be high, many early-stage solar power systems or solar PV systems will soon reach the end of their lifecycle. Mingxin is well-prepared to provide industry-leading end-of-life management solutions for both commercial and consumer solar systems.

The remaining components in solar panels consist of high-quality glass, aluminum frames, polymers, silicon, copper, and silver paste (used for printed conductors on each cell). All of these components (≥95%) can be successfully recycled.

Recycling Process

1. Disassembly Process

Initial Disassembly

An automatic framing machine is used to remove the junction box of the solar panel and the surrounding aluminum frame from the solar PV panel. This step makes the subsequent processing more efficient and reduces the need for manual handling.

Softening Process

After removing the frame, the PV panel is transferred to a softening furnace. Inside the furnace, heated tubes uniformly bake the glass panel, which softens at high temperatures to dissolve the EVA film. This process facilitates the subsequent peeling of the glass from the backsheet.

Glass Separation

After the softening process, the PV panel is conveyed to the head of the machine. At the spindle box position, there are two rollers. The PV glass panel is fed into the center of the rollers and squeezed to move forward.Meanwhile, the glass panel is mechanically crushed and separated by a knife (moving reciprocally left and right). The separated glass fragments flow downward at the outlet and are manually collected and processed, while the glass sheet is discharged from the top and also collected manually.This automated disassembly and processing process ensures the effective recycling of PV panels, while reducing manual intervention and improving overall processing efficiency and safety.

2. Crushing and Separation

Shredder

Materials enter the shredder via a conveyor. The shredder has staggered blades mounted on two shafts. During the rotation of the two knife shafts in opposite directions, the blades shear and the knife teeth tear the materials to crush them into smaller pieces. The crushed materials are then sent to the next shredder via a conveying device. The output size of the shredder is 3-4 cm.

Granulator

The crushed materials are conveyed to the granulator via a conveyor. The granulator is composed of blades and a blade disk. Through the high-speed rotation of the blades, the crushed materials are further crushed and granulated by impact, to facilitate the subsequent vibrating screening process. The crushed materials enter the next process via a negative-pressure air system. The granulator is equipped with a 2.8 mm sieve.

Vibrating Screen

The heavier materials collected by the analyzer fall into the inlet of the classifying screen. After screening, the materials with the required particle size enter the gravity separator for the next separation step, while the materials that do not meet the required particle size are sent to the next grinder for further grinding. The classifying screen is a single-layer screen with mesh sizes ranging from 10 mesh to 20 mesh.

Turbo Mill

Materials that do not meet the particle size requirements for separation by the classifying screen are further ground by the turbo mill and then flow into a collector via an induced draft fan for subsequent processing.

Gravity Separator

After being ground by the mill and screened by the classifying screen, the materials that meet the particle size requirements enter the gravity separator respectively for further separation and processing. The front outlet discharges heavier metal powder, while the rear outlet discharges lighter mixed powder of metals and plastics.

Electrostatic Separator

The mixture separated at the rear end of the gravity separator is sent to a high-voltage electrostatic separator via a spiral auger and a bucket elevator. In the electrostatic separator, resin powder and copper powder undergo the final separation process, resulting in pure resin powder and copper powder.

Pulse Dust Collector

The dust and ultrafine powder generated during the operation of the entire set of equipment will be collected and discharged under negative pressure for treatment.

The Complete Solar Panel Recycling Solution-Solution-Jiangxi Mingxin Metallurgical Equipment Co., Ltd.

The Complete Solar Panel Recycling Solution-Solution-Jiangxi Mingxin Metallurgical Equipment Co., Ltd.